Tag: 3D Print

-

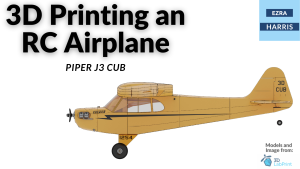

3D Printing an RC Plane

I spent about three weeks working on 3D printing an RC plane. I had initially searched for a somewhat easy RC plane to print and assemble as I’ve never had any experience with RC vehicles in general. I eventually found a good model that was both free and looked simple enough for me to be…

-

Using a DSLR Camera with Octolapse for Stunning 3D Printing Timelapses

Recently I bought a used Canon SL1 camera; it’s an old but great camera to use as a webcam or any general-use camera taking. One benefit is that it works with a lot of software using the USB port to capture a live video feed from the camera. When using the USB port it does…

-

Tuning Acceleration on my 3D Printer

Yesterday I got my Printrbot Simple Metal plus running, I had gotten it previously running, but it had significant build issues, mainly with no ease of access of the motherboard, when I designed the adapter for the SKR 1.4 motherboard to fit into the old Printrbot motherboard slot, I had no way of accessing the…

-

Upgrades for my Ender-3

I finally got around to fixing and upgrading my Ender-3. I’ve had my Ender3 for almost 2 years now and have occasionally been upgrading when needed. Last year I made my best upgrade to the “silent board” TMC2208 stepper drivers. Which significantly silenced the noise of the printer when printing. As well as a BL…