Author: ezradharris

-

Learning through Self Implementation of Features

I recently covered FreeShow, a software made for presentations in Churches. One of the features that I liked and talked about was the open-source nature of the App. In this case, open-source means having the app’s code publicly available on GitHub, with any changes made, issues, or additions to its Codebase available to read /…

-

Ditching Google for an Open Alternative

In the event of researching software for my church to help streamline the streaming process and slideshows. Initially utilizing less ideal software for A/V, I’ve found some fascinating tools that directly target my problems with the software we were using; whether directly targeting churches or not, I’ve come across many solutions. The “it works” problem:…

-

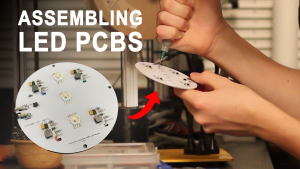

Neopixel Frustrations to Custom RGBW LED Modules

The design for the light module comprises four main controlling components, BGRW (as shown in the animation below. Each part is individually controlled via 4 PWM signals from the flight controller addressing each light color:

-

React State – MFED 03

A new concept I’m starting to learn in my Coursera course on React Basics (view post series here) is React “States.” States in React is an interesting way of storing the “state” or current information about a variable or function. ⓘ As a new topic, I’m still learning how React works. For an actual professional,…